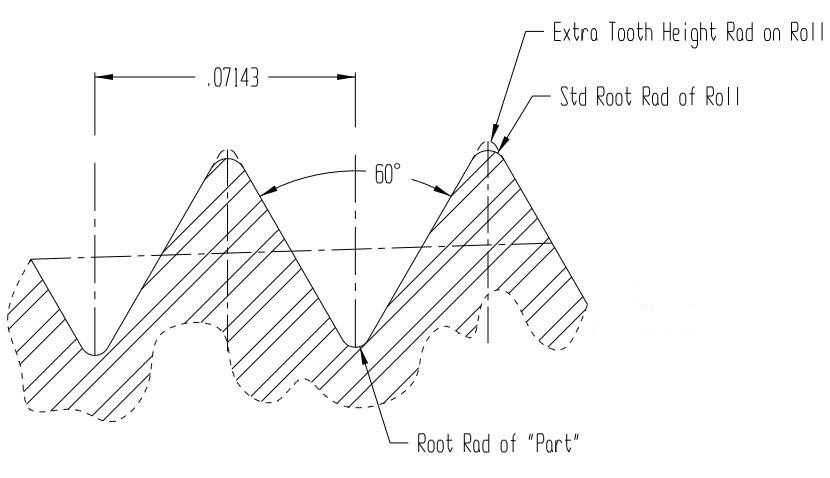

CJWinter designs a special tooth form that allows more material to be rolled into the root of the roll and a sharper crest on the part.

For US and Metric threads, this delivers additional adjustability between the major and pitch diameter specifications.

The Process: CJWinter’s Extra Tooth Height Form reduces the root radius of the thread roll and increases the tooth height of the part being rolled. The process is sometimes used to allow for the rolling of parts when controlling the blanked diameter is a challenge.

Straight Threads: Allows more adjustability between the Major and Pitch diameter specifications

This process also allows threads to have an appearance of being burnished, due to the sharper form being produced. Some also provide relief in the thread roll’s root if the part is over-rolled during the cold form process. Sometimes the crest radius of the part is sharper on or below the minimum radius allowance.

Availability: Simply specify “Extra Tooth Height Form“ when ordering your thread rolls from CJWinter on our Request for Quote page and we will provide the required geometry for this process at NO EXTRA CHARGE!

Click here to request the Extra Tooth Height Form for your application.