Solutions Are Our Product

CJWinter provides thread rolling and forming for a variety of thread rolling attachments and thread rolling machines.

Product Catalog

Free Download

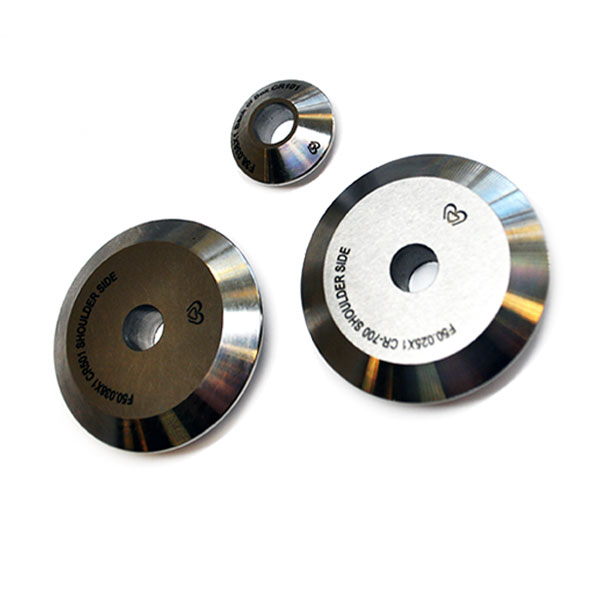

Attachment Rolls

CJWinter manufactures a wide range of attachment thread rolls. Our quality and performance is unsurpassed, and standard size thread rolls ship within 24 to 48 hours.

Thread Rolls for Major Manufacturers

CJWinter manufactures thread rolls to fit attachments from all major manufacturers, including Reed, Salvo, Detroit, and Fette E - Fette T, ER, A22.

Cylindrical Rolls & Machine dies

CJWinter is the world leader in machine dies. CJWinter typically can meet your exacting thread roll specifications a full 2 to 3 weeks faster than our leading competition.

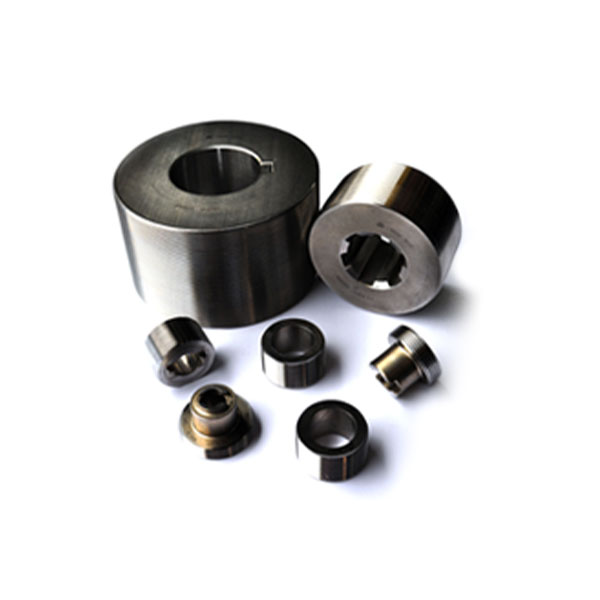

Knurls and Splines

CJWinter Knurls are designed to your print. Knurls are made to extremely high standards from the finest materials available. The care and precision used in their manufacture assures the user of a premium quality tool.

MAThread

MAThread® is a patented threaded fastener used mainly for the auto industry for improving product assembly. The cutting-edge technology of MAThread eliminates the common issue of cross-threading.

Burnishing Rolls

CJWinter Burnishing Rolls are designed to your print. Burnishing Rolls are made to extremely high standards from the finest materials available.

Sucker Rods

If you manufacture Sucker Rods, Pony Rods, Sinker Bars or Couplings, in either AISI Grade or API Grade Alloy, CJWinter is the Best Choice for your thread rolling needs. Available in 5/8", 3/4", 7/8", 1" & 1 1/8" body diameters.

API Cold Rolls

Drill pipes undergo repeated, severe tensile stresses during a drilling operation. These cyclic stresses are particularly focused on the thread roots and can cause premature pipe failure.

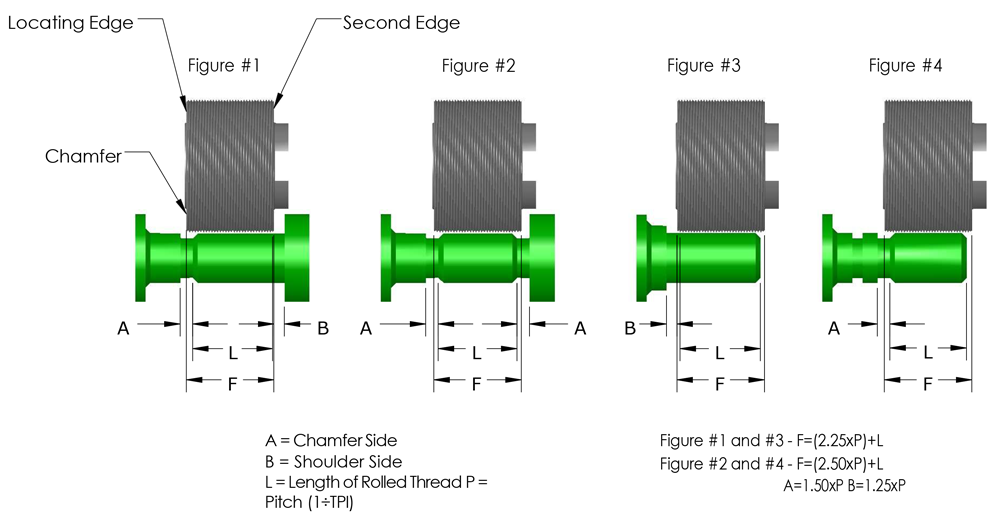

How to Determine Correct Working Face

The working face (or F dimension) of the thread roll must always be greater than the length of thread that needs to be generated on the part. The general rule is to allow the thread roll to overhang each end of the blank by at least 1 1⁄4 threads (root to root or crest to crest = 1 thread).

Figure 1 and 3 F = (2.250 x P) + L

Figure 2 and 4 F = (2.500 x P) + L

A = 1.500 x P

B = 1.250 x P H

Whether you’re ordering from our extensive in-stock inventory, or requesting custom-made materials, the thread rolls you get from CJWinter arrive quickly, perform at your exact specs, and last a long, long time.

How to Order Thread Rolls

- Make and model of thread rolling attachment

- Style of thread roll (i.e. D-1, DR-1, C-1, etc.)

- Size and pitch of thread to be rolled, including dimensional tolerances if other than standard

- Length of thread on part

- Material to be rolled

- Print of part to be rolled

NOTE: Special rolls may require a sample part or more detailed specifications. Some rolls require a special calculation to figure the work face on the roll.

knowledge base

learn more from our blog

How Controlling Major Diameter Can Extend Thread Roll Life and Cut Your Costs

In precision manufacturing, even minor deviations can lead to significant issues. One critical factor often

Optimizing Thread Rolling with Precision Calculators

Thread rolling is widely recognized for its ability to produce strong, reliable threads without removing

AMERICAN STANDARD EXTERNAL TAPER PIPE THREADS

The United States uses ANSI’s American National Standard Pipe Thread Standards to regulate the formation