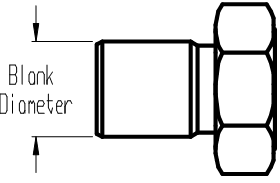

An incorrectly sized blank diameter can result in thread rolling issues like tapered threads, slivers and flakes, and off-size threads. You need a Blank Design.

Blank design, therefore, is an important consideration in the thread rolling process to ensure parts are manufactured to the highest quality.

Important factors to consider during blank design include:

- Blank diameter

- Chamfer angle

- Shoulder clearance

- Thread length vs. roll length

Changes to the blank diameter will affect the major diameter of the thread by a ratio of 3 to 1. So, for every .001” that the blank diameter is adjusted, the thread’s major diameter will change by .003”.

CJWinter compiled helpful diagrams of blank diameter, chamfer angle, and other dimensions involved in blank design so you can quickly identify or correct any thread rolling issues you may be having.

Lib Pietrantoni

Lib has been with the Brinkman International Group, Inc. for the last 30 years. Currently, the Director of Global Sales, Lib has held numerous positions in Engineering, Operations, Sales and Product Management with CJWinter and its manufacturing divisions. Lib is a member and has served on governing boards for the Society of Automotive Engineers, The American Society of Mechanical Engineers, and the Precision Machine Products Association.