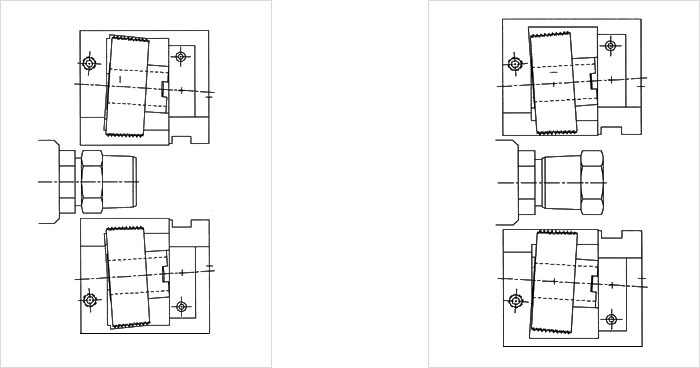

The Patented "Matched Taper For pipe threads" design helps eliminate flaking and slivering.

The radial infeed and equalized thread rolling pressure eliminates part deflection to improve thread concentricity.

This exclusive process matches the large diameter of the thread roll to the large diameter of the blank to eliminate the mismatch of the thread rolls on the work piece and attachment "walking" on the part.

This system is available in the 134-SA and 162-SA models.

A retrofit kit is also available for the 134-SA and 160-SA or larger attachments.

Matched Taper for Pipe Threads :Q2 and K2 Style

knowledge base

learn more from our blog

How Controlling Major Diameter Can Extend Thread Roll Life and Cut Your Costs

In precision manufacturing, even minor deviations can lead to significant issues. One critical factor often

Optimizing Thread Rolling with Precision Calculators

Thread rolling is widely recognized for its ability to produce strong, reliable threads without removing

AMERICAN STANDARD EXTERNAL TAPER PIPE THREADS

The United States uses ANSI’s American National Standard Pipe Thread Standards to regulate the formation