The United States uses ANSI’s American National Standard Pipe Thread Standards to regulate the formation and sizes of screw threads on manufactured parts with straight or tapered threads. These standards ensure that separate pieces fit together properly for specialized attributes such as pressure-tight sealing and rigidity.

Recent Posts

Thread rolling is a metal forging process that forms threads into the mirror image of a roller die. The process is different from metal cutting, grinding, and chasing because it does not remove any metal from the workpiece. Instead, thread rolling uses hardened steel dies to displace and mold ductile metals. The high-pressure process physically changes the properties of rolled metal parts to make the base part and the threads harder and stronger.

Most frequently used in the production of threaded rods, bolts, screws, and other metal fasteners, thread rolling is a cold metal forming process that creates threads using precision thread rolling dies that are the mirror image of the thread being produced. Though a reliable and flexible practice, there are a number of techniques that can improve your output. Extensive experience in thread rolling makes CJWinter’s team of well-versed experts the go-to source for anticipating and preventing common thread rolling problems.

In these unprecedented times, and their ever-changing, always-challenging impact on manufacturing and supply chain, CJWinter would like to let you know that while supremely focused on safeguarding the health and welfare of our workforce, we remain committed to providing superior customer & partner services. We continue to produce the highest quality thread rolls with unparalleled delivery times.

Since the company’s incorporation in 1956, the team at CJWinter developed a reputation for the fast and efficient production of thread rolled products. Our top priority is giving customers a competitive advantage, which we do by leveraging experienced engineers, superior customer support, and online resources.

Every year, the PMPA Technical Membership Chairman’s award is given to the outgoing Chairman in gratitude for his or her exceptional leadership and service throughout the year. We are proud to say that this year, CJWinter’s own Liberato Pietrantoni received the award for his work in this role. It was a great year for PMPA and our company, and we’re happy to have worked closely with this organization.

CJWinter began as a supporting manufacturer for Davenport screw machines. Over the years however, the company has expanded its product offerings to include a complete line of thread-rolling dies, both for internal use and for other manufacturers, and has found great success due to a passion for excellent customer service. CJWinter is also a member of PMPA and continues to benefit from the organization’s networking opportunities, wealth of information and access to educational materials.

CJWinter's success story has recently been featured in a Production Machining Magazine article:

After recently presenting at the 2016 PMPA National Technical Conference, CJWinter will now head to northern Ohio to share thread rolling troubleshooting tips.

CJWinter will join PMPA's Northern Ohio Chapter on May 10, 2016, for an "All Things Threading" session in Brecksville, Ohio.

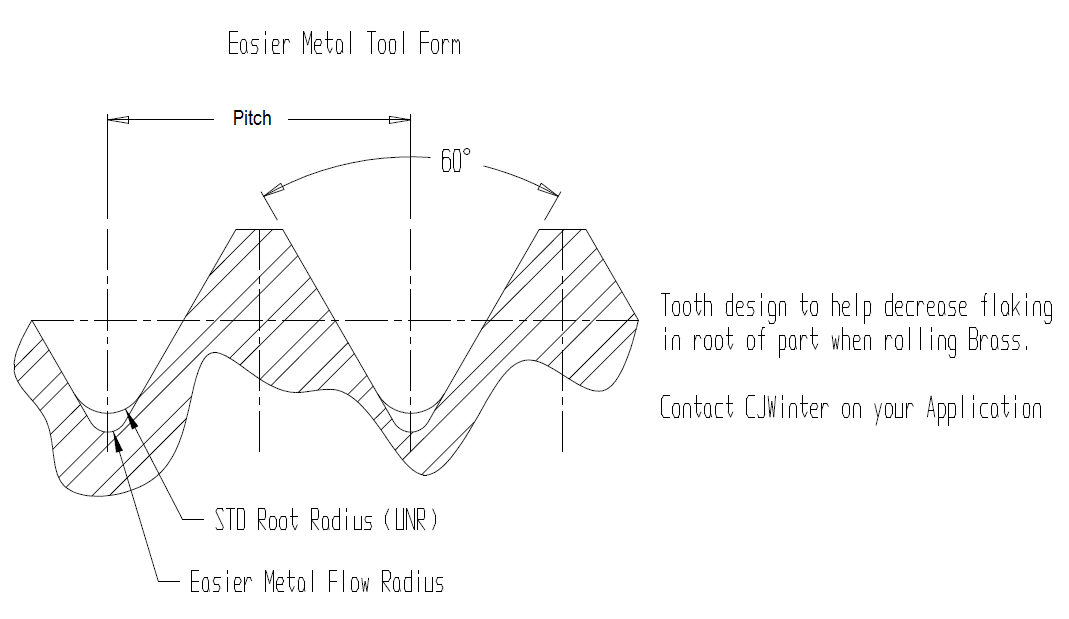

CJWinter designs a special tooth form that allows more material to be rolled into the root of the roll and a sharper crest on the part.

For US and Metric threads, this delivers additional adjustability between the major and pitch diameter specifications.

More manufacturers in the automotive, fastener, plumbing, aerospace and other industries are choosing thread rolling over the traditional thread cutting process.